PRODUCTS CENTER

Raw material:

1)Condenser tube:Coil welded steel pipe¢4.76~¢8×0.71

2)Heat transfer wire:Low carbon steel wire¢1.2~¢1.6mm

3)Support:Cold rolled sheetT=0.6~2.0mm

4)Heat sink:Cold rolled sheetT=0.6~0.8mm

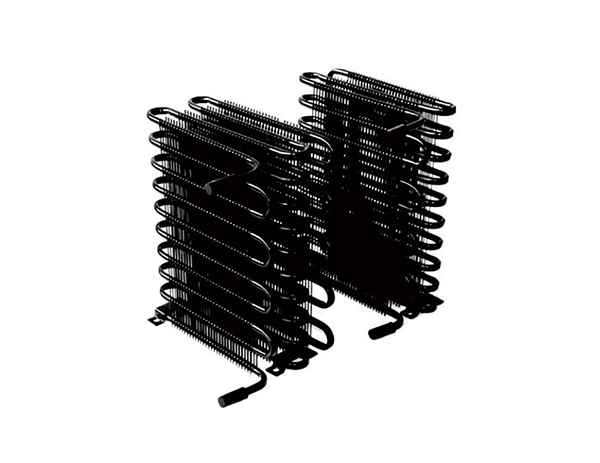

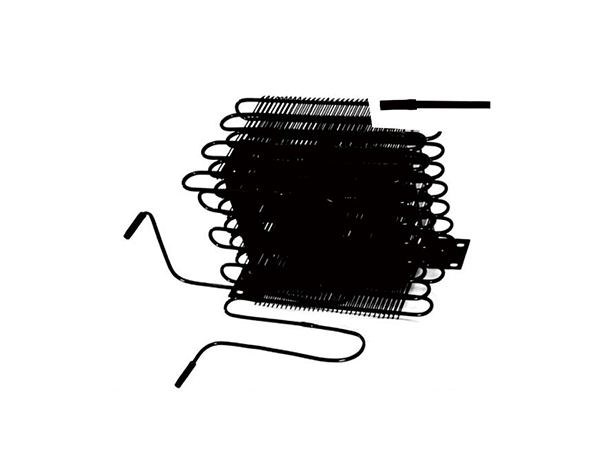

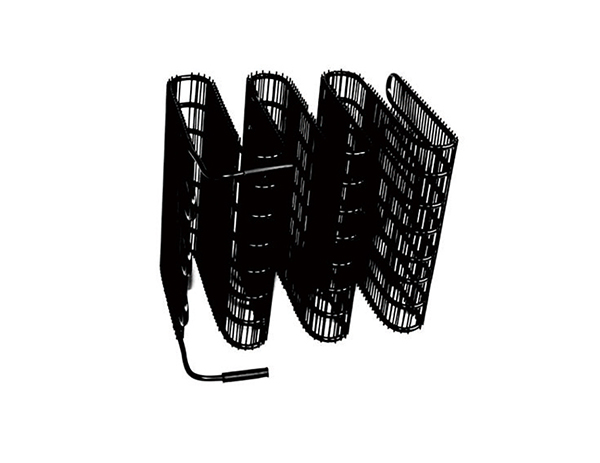

Structure type:

Main process:

Bending pipe, wire tube welding, mounting bracket, welding of inlet and outlet pipes, (folding or bending forming), leak detection, cleaning, surface coating, inspection, packaging

Technical skills:

The wire spacing is ≥5mm, which can be made according to the customer's drawings and sample requirements, and can assist customers in product design and manufacture of various types of refrigerators for refrigerators and freezers.

Product performance:

| Technical Parameters: | |

| R134aStandard for piping in refrigeration systems | Coating quality performance standard |

|

Residual moisture ≤5㎎/100cm3 Residual impurities ≤10㎎/100cm3 Residual mineral oil ≤100mg/100cm3 Residual chloride ion ≤5vloppm Residual paraffin ≤3mg/㎡ Maximum single impurity ≤0.5mm |

Coating thickness:

Cathodic electrophoretic paint film thickness 15 ~ 20μm

Coating hardness: ≥2H

Impact resistance of coating: resistance to 50cmg.kg/cm without cracking

Coating adhesion: ≥2

Coating flexibility: bending R=3D, bending angle 180, no cracking or peeling off of the coating

Coating corrosion resistance (salt spray test GB2423):

Cathodic electrophoresis ≥72h

|

Language

Language